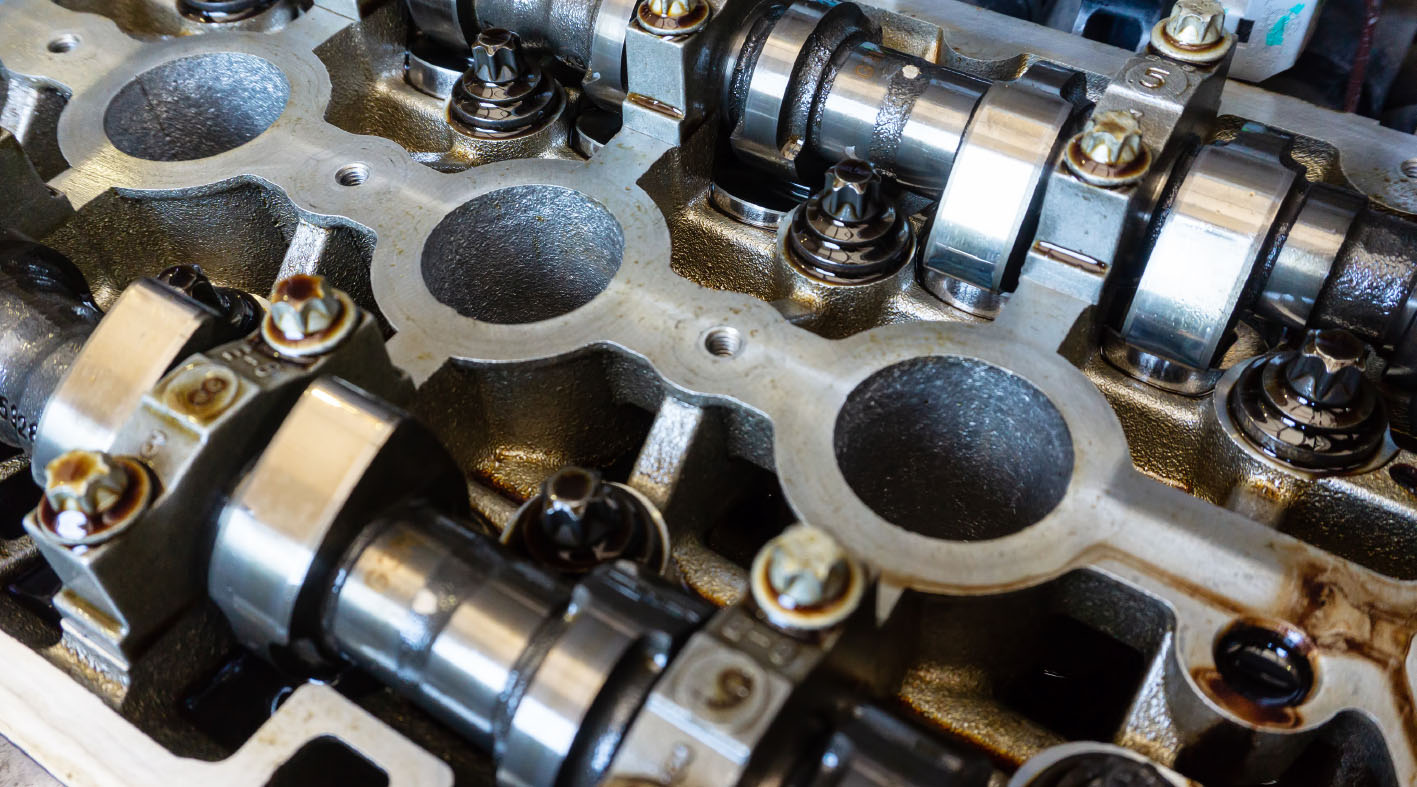

Cam followers

Good to know!

Mechanical or hydraulic valve lash adjustment?

Hydraulic valve lash adjustment has already been established in series production by vehicle manufacturers for decades. Low noise emissions and maintenance-free operation speak for the use of hydraulic valve lash adjustment. However, hydraulic compensation elements also have their limits. These are limited by valve accelerations and the associated speeds. An engine with hydraulic valve lash adjustment should not be run above the maximum speed advised by the manufacturer. However, if you want to access a wider speed range and rev above the engine's maximum rated speed, conversion to mechanical valve lash adjustment comes into play. Mechanical valve lash adjustment is much more stable and allows higher valve accelerations and speeds. Even modern sports and racing engines resort to this nowadays. Unfortunately, this type of compensation does not require little maintenance. The valve lash must be checked and readjusted regularly.

Why do the cam followers need to be replaced?

The two running partners (camshaft and cam follower) run in on each other during the first hours of operation. This results in a matched contact pattern. If cam followers that have already been used are used again, it can happen that an existing contact pattern on the cam follower leads to uneven load distribution on the cam running surface. In some places, this leads to overloads and corresponding camshaft failures.

Can I convert from hydraulic to mechanical valve lash adjustment?

In many cases, it is possible to convert from hydraulic to mechanical valve lash adjustment. In this case, the hydraulic element in the cam follower must be replaced by a rigid element. We offer a corresponding compensation element for bucket tappets. This is available in different diameters and lengths to provide you with the right solution for a wide range of applications.

Can I run mechanical profiles with so-called "hydro tappets"?

No, this is not possible. The mechanical profiles have different inlet and outlet ramps. The acceleration ramp is usually much higher and could lead to failure of the hydro element in the cam follower. Consequential damage cannot be ruled out in this case.

The full assortment

Schrick dealer network

As a private person, you can rely on our network of selected dealers. Use our dealer locator. Your dealer is your local partner and is available when planning your project and can support you in selecting the right engine components.

Are you a commercial business person and would like to become a SCHRICK dealer? Just give us a call.