About Schrick

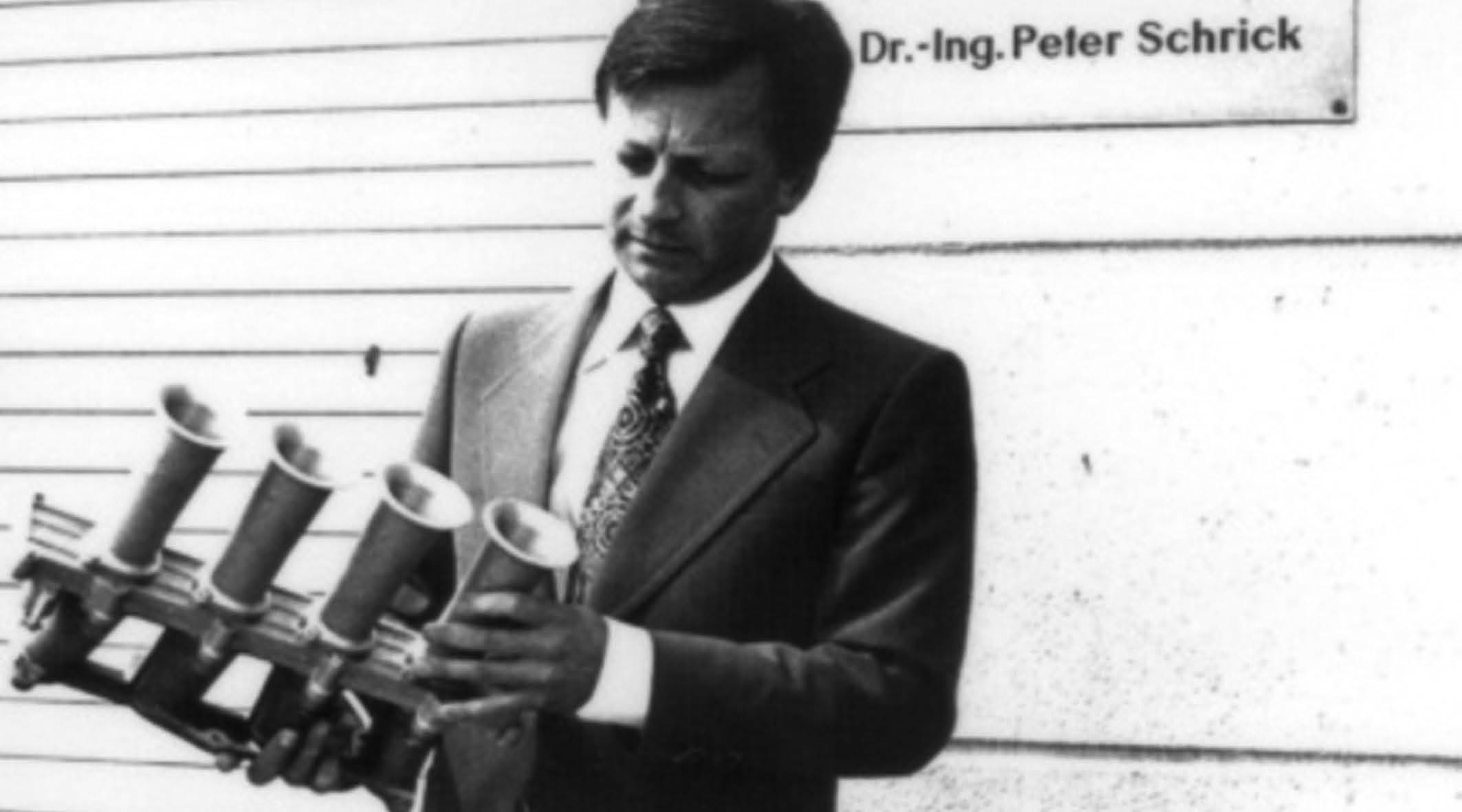

The company was founded in 1969 by Dr. (Eng.) Peter Schrick. With his unlimited enthusiasm for motor sports and devotion to engine construction and development, an international company was formed with three locations in Germany and over 300 employees. The headquarters in Remscheid developed into a technology centre with development, engine testing and one of the most advanced manufacturing centres.

For more than five decades now, the name SCHRICK has stood for high performance components available in the motor sport, tuning and vehicle refinement areas. Schrick offers its customers not only the development of total-motor systems, the largest range of high performance camshafts and valve drive components in the highest quality.

Quality management

- At Schrick, even the smallest component is subject to a 100% quality inspection. For this is the prerequisite of a professional cooperation for us also in the retail business.

- Our customers in tuning and motor sport have relied on the consistently high quality and unmatched precision for years. The powerful features of our quality assurance include coordinate and form metrology as well as surface and contour measurements.

- There is a good reason that Schrick has been DIN ISO 9001 and TS 14001 certified for many years and supplier to the premier class of motor sports.

History

1969 – 1973

1969 Foundation of the company and first racing activities of Dr. (Eng.) Peter Schrick in the BMW 700

1972 Development, testing and production of Formula 2 engines

1973 First major successes with Schrick engines in numerous championships

1974 – 1982

1977 Schrick becomes European champion with a specia

1980 Development and production of the Opel 2.4l racing engines

1982 Development and production of a water-cooled 1.6 litre racing engine with 200 HP for VW

1983 – 1990

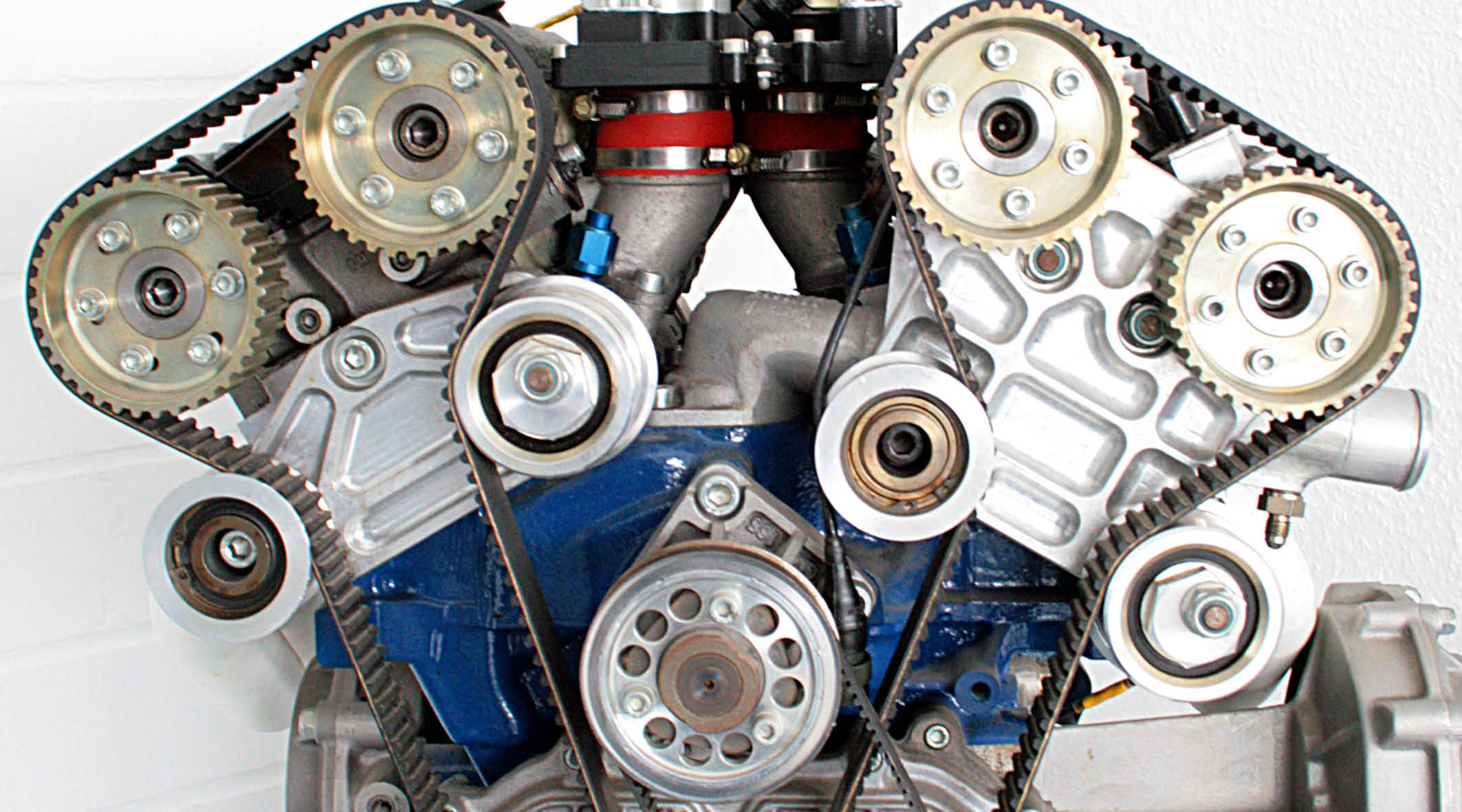

Development of V6 contest engines for Opel in the DTM use of the most modern CAD systems for analysis and design of engines

1991 – 2002

For our high-performance camshafts, Peter Schrick developed the swing-boost effect. Due to high valve accelerations, the cylinder filling could be increased via the excitation of the gas column in the intake tract. Despite short valve opening times, this results in very high performance gains.

2003 – 2012

2006 Dr. Schrick GmbH became AVL Schrick GmbH. The largest privately owned and independent engine, drive train and test bench developer from Graz takes over Schrick. Only one thing changes: With our strong partner backing us, even more share knowledge goes into the tuning programme.

2012 – 2014

With the Schrick brand concept, we build a more personal relationship to our customers! Because from 2013, we will support our customers with our SCHRICK CLASSIC programme for vintage and new cars. Our SCHRICK PERFORMANCE programme is currently setting up with the latest products and developments. The latest technologies for turbo and direct injection engines make the camshaft a sought-after tuning part here too!

2015 –

Newest technologies for turbo-charged and GDI engines finds one´s way into the world of tuning. Schrick has started exactly here with their research and development of new products. This makes a camshaft still to an essential part of a tuning program. Ask for example for our fuel injection pump cams! Besides will meet more and more variable valve train systems the tuned cars. Did you know that SCHRICK is the only camshaft manufacturer how offers camshafts for BMW Valvetronic engines?

Facts & Figures

900.000.000 Cycles

9 x 10^8 Cycles should a camshaft lasts in an engine. Written: 900.000.000 . Thats ok for a Schrick cam!

> 10.000 laps lead

Over 10.000 laps lead have our camshafts seen in all racing series worldwide. From Formula 1 to the famous 24h Races of Daytona and Nürburging.

100% Excitement

Enthusiasm and most of all fun connects Schrick engineers today as it did in the days of motor sport & tuning!

40 CNC-cells

CNC-cells modern and continuously maintained, leads us to machine your engine components in highest precision. Especially the camshaft you can purchase, is looking for appropriate competitor.

8 Digits

8 Digits are necessary to define an equicontinous cam profile. This fact ensures best profile quality during cam calculation and machining on our CNC-machines.

0,001 Millimeter

Micrometer is the band of the repeatabiliy on our measuring devices to deliver you perfect quality.

Schrick image film

Schrick Technologies

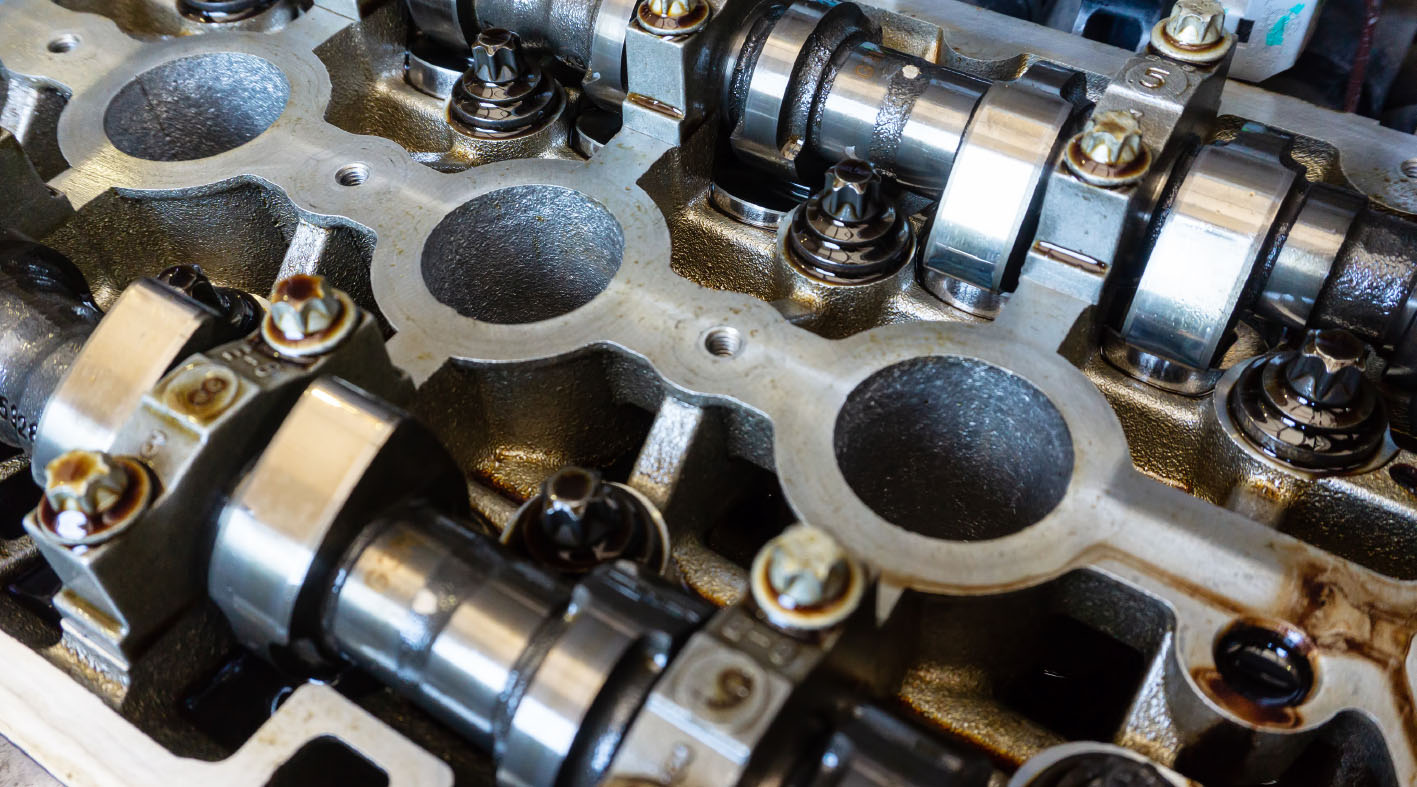

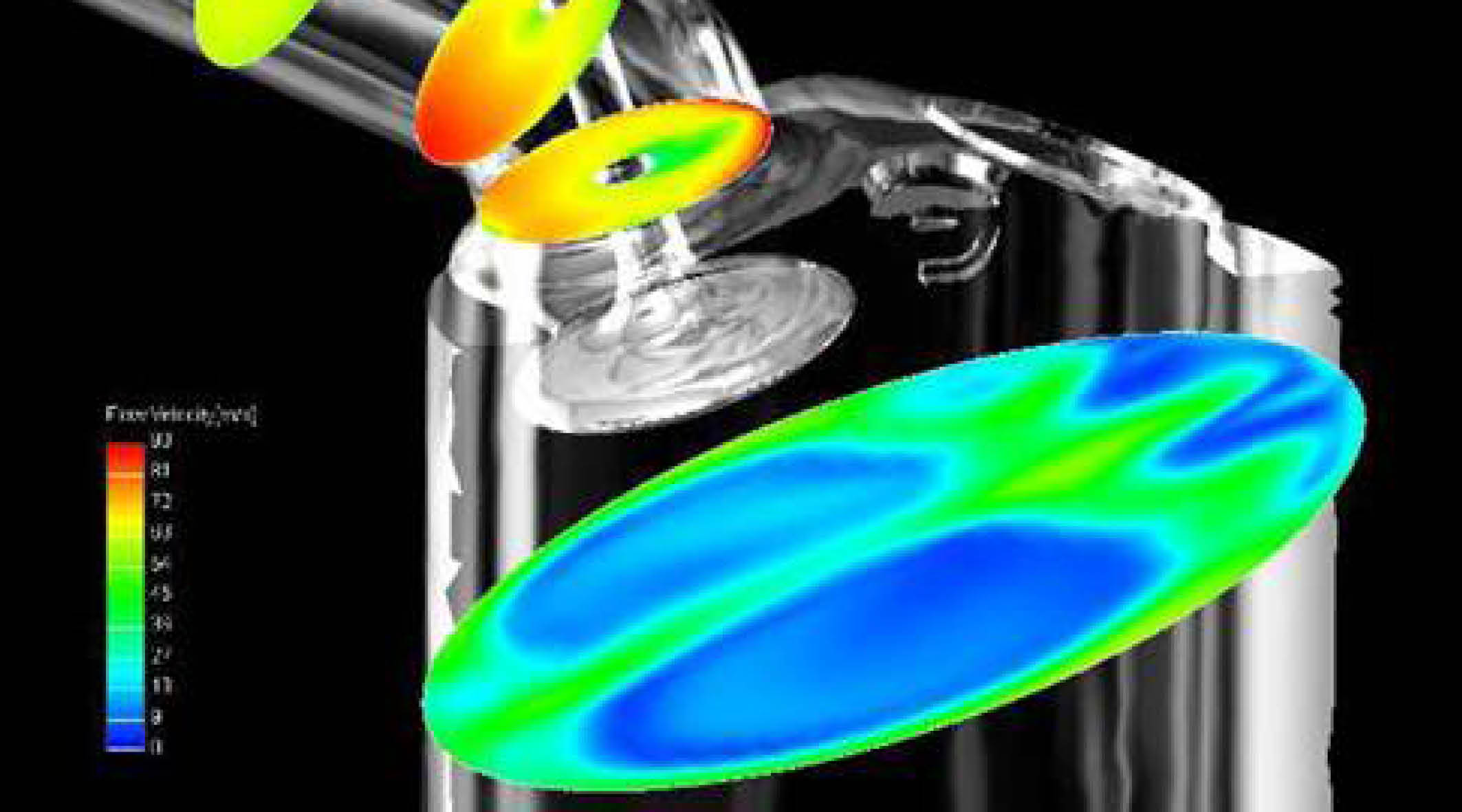

3D Lobes

Over decades of development, optimised structural profiles (perpendicular to the running direction) have been developed at Schrick. The so-called 3D lobes with spherical character increase the stability of the camshafts with their optimised structural behaviour and the promotion of lubrication film formation. For this reason, our camshafts easily measure up in highly stressed engines. Positive side effect: friction is minimised!

Precision Lobes

Profile precision in ?-range (1/1000 mm) as is only possible in Formula 1. Each cam profile manufactured by Schrick is the same. This not only ensures smooth running but also guarantees reproducibility in the engine construction for experienced engine builders and tuners. We ensure this through integrated precision metrology in the process.