Willkommen im neuen

Schrick Online-Shop

Das Schrick Händlernetzwerk

Als Privatperson können Sie auf unser Netzwerk aus ausgesuchten Händlern zurückgreifen. Nutzen Sie hierzu auch unsere Händlersuche. Ihr Händler steht Ihnen als Partner vor Ort gerne bei der Planung Ihres Projektes zur Verfügung und unterstützt Sie bei der Auswahl der richtigen Motorenkomponenten.

Sind Sie gewerbetreibend und möchten gerne SCHRICK Händler werden, so kontaktieren Sie uns per Mail oder nutzen Sie unsere Händleranfrage im Loginbereich.

Unsere Empfehlungen

Unsere Geschichte

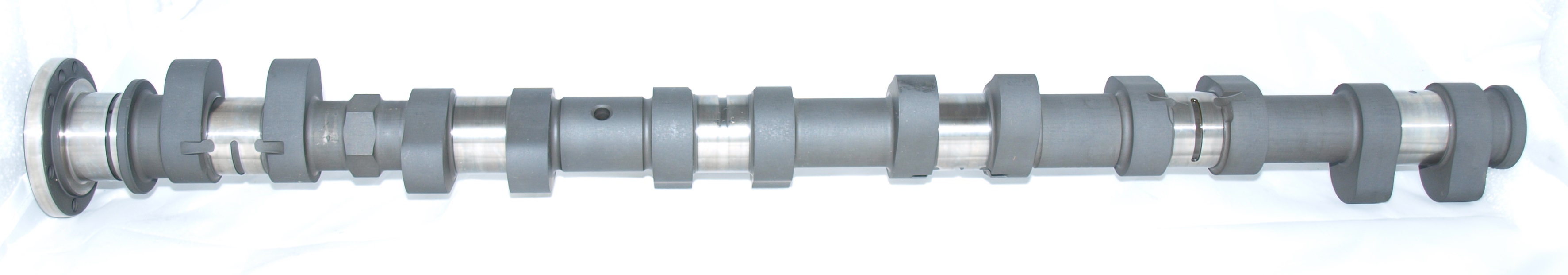

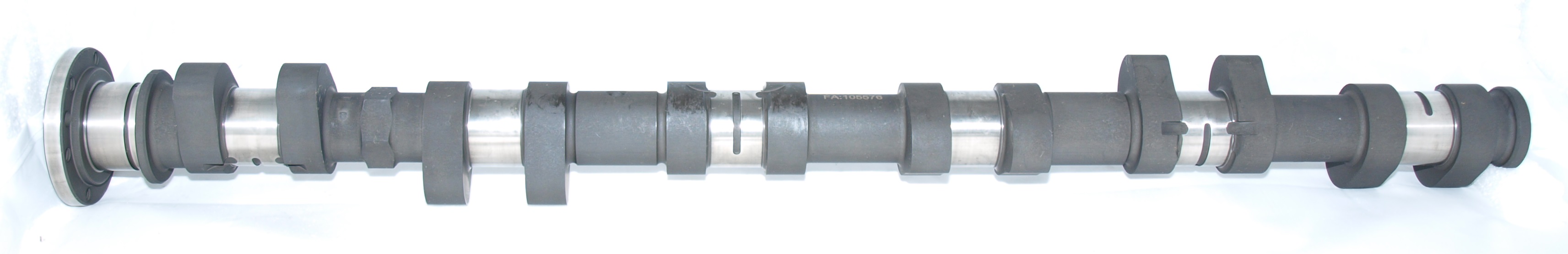

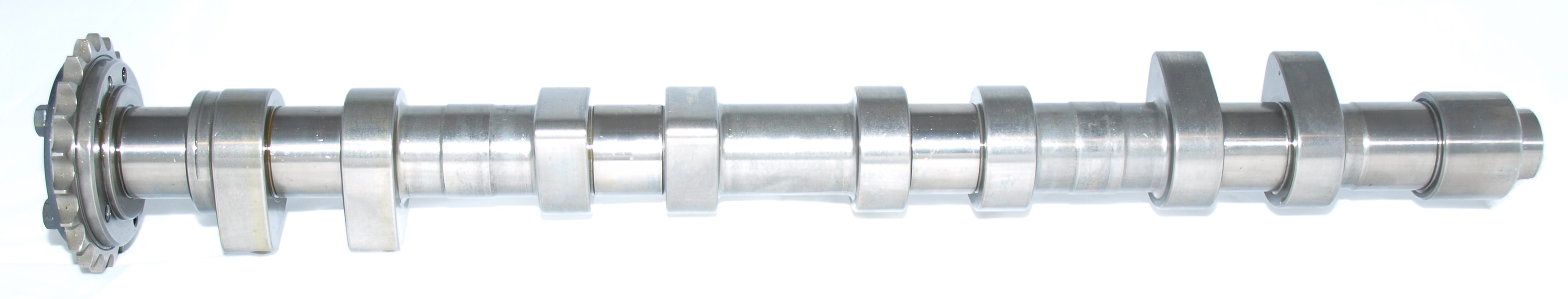

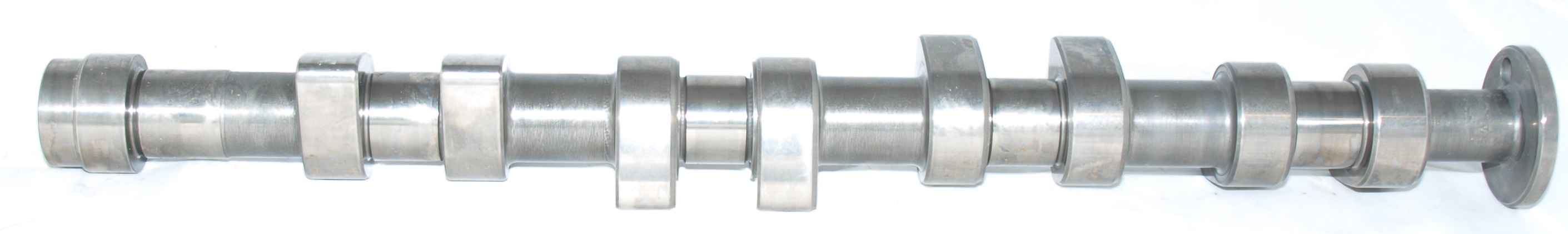

Seit über fünf Jahrzehnten steht der Name SCHRICK für Hochleistungskomponenten im Bereich Motorsport, Tuning und Fahrzeug- Veredelung. ...